- Daily & Weekly newsletters

- Buy & download The Bulletin

- Comment on our articles

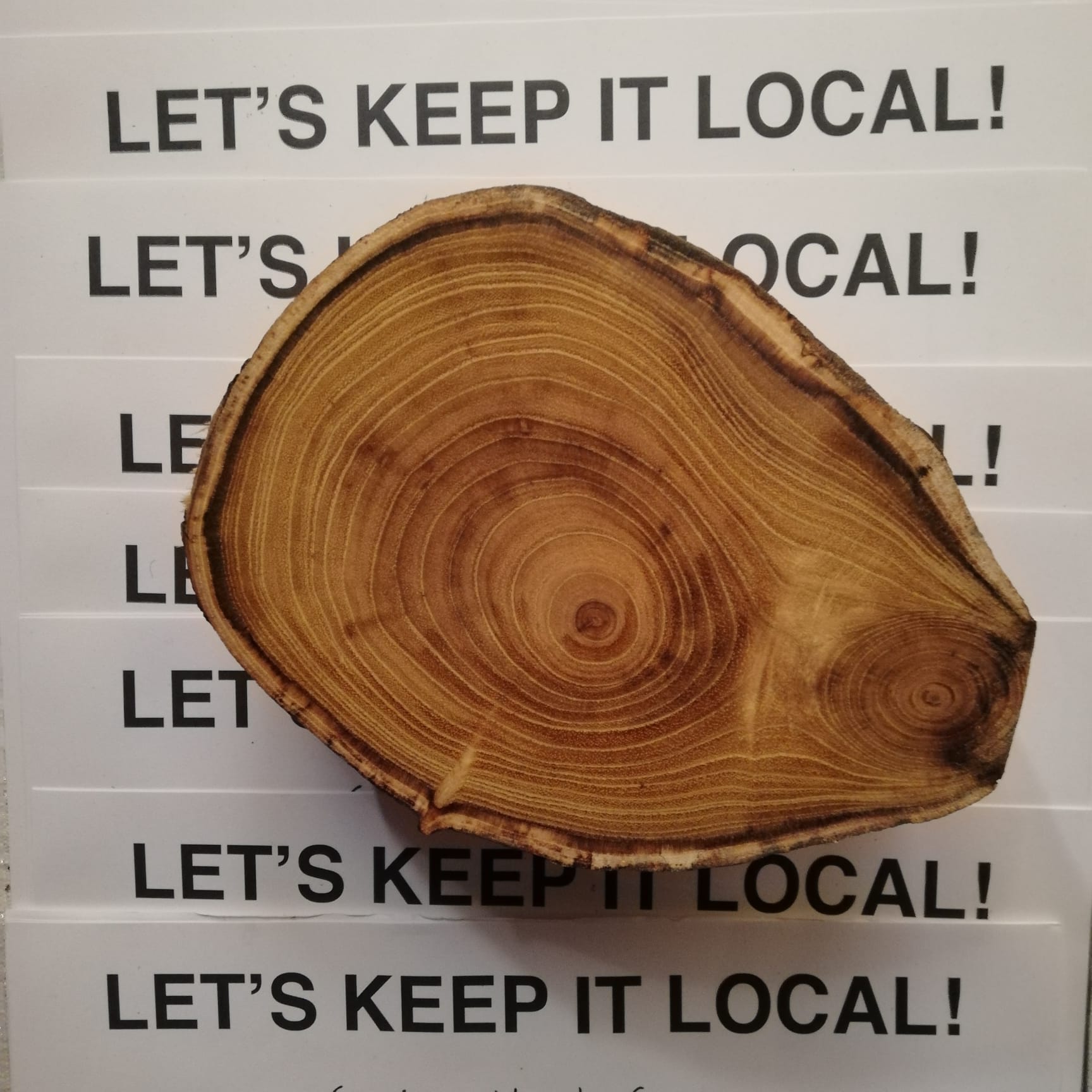

'Wood from Sonian Forest should stay in Brussels': Group plans local alternative to exporting to China

Every year, thousands of tonnes of wood from the Sonian Forest is shipped to China - where it is made into objects that may well come back to Europe at great environmental cost.

Now a new Brussels co-operative has been formed with the aim of keeping the wood here and transforming it locally, creating added value for the economy.

The Sonian Forest is remarkable in a number of ways. A 10,000-acre forest located so close to a major city centre is extremely rare - and it has never been cleared for agriculture, so the topography has not changed in thousands of years.

Some 80% of the forest is beech trees, thanks to extensive planting during the Austrian occupation (1714-1796), which has created awe-inspiring cathedral-like environments due to the very tall, mature trees.

But what a lot of people do not know is that the Sonian Forest is also a major producer of timber - 20,000m³ per year. To appreciate how much wood that is, it takes three full-size lorries to transport just 100 cubic metres.

How is it that so much wood is being produced? Beech trees have a lifespan of 150 to 350 years. As part of the management of the forest and planning for the future, old, infirm or potentially dangerous trees are harvested and replaced by young trees.

Since about 10 years ago, three quarters of this wood is exported to China. Beech wood is highly appreciated for its hardness, beauty and the fact that it does not splinter. It is prized for flooring, furniture manufacture, kitchen utensils, tooth picks and ice cream bar sticks. It is also widely used in architecture - as structural material, interior scaffolding and partitions of walls.

The Sonian Wood Coop has been formed with the objective of doing things differently - bringing together local carpenters, traders and forest management.

"We create a local value chain," says Stephan Kampelman, economist at ULB's faculty of architecture. "If you own a Belgian sawmill and your job is to create toothpicks you will never be competitive with China.

"But if your output is to create fine school furniture, tailor-made for our schools, you have a huge market because the value you create is so much higher. That’s our strategy: to use this prestige and the quality of the local wood to create more value."

He adds: "The final products are not necessarily more expensive because we can avoid transport and we can avoid intermediaries. Let’s get the production costs lower by doing things locally, by making sensible steps in terms of investments, and getting the right technology to do economically viable things here in Belgium."

The co-operative is 90% of the way towards meeting its €15,000 Growfunding target and is appealing to anyone who "thinks that the Sonian wood should stay here in Brussels". The money raised will be used to buy a first batch of wood from the forest.

"To get things going, we think that it’s necessary to show people what this local wood looks like, to start making a couple of really tangible projects so people can see and feel what this Sonian wood is," says Kampelman.

"For this first step to work, we need the support of the people of Brussels. They need to say: OK, we understand that there’s a potential here, we understand that there’s an issue, there’s room for improvement. Supporting this initiative sends a clear signal to everybody - to the carpenters but also to the politicians of the city that this is a useful and relevant project."

Is this really a feasible project? "In Amsterdam they produce only 2,000m³ of beech wood but it's still enough to keep a little sawmill going," says Kampelman. "So with Brussels' 20,000m³ this is definitely possible. And what helps make it possible is the cachet, the provenance and the narrative of the wood.

"If you have floorboards in your home and you know that they come from the Sonian Forest it’s different from having floorboards that you don’t know where they come from. Maybe they have been cut in environmentally disastrous consequences - who knows, the chances are they have been. So it’s a way to create a better relationship with the materials that we have around us in our lives."

Comments

What does « at great environmental cost » mean? The transport emissions from shipping or do they go to China by train from Liège? Any other costs?

Not that this isn’t a commendable initiative but I can imagine the sonian timber is FSC/PEFC certifiable, contrary to most wood processed in China. So actually a relatively sustainable affair?