- Daily & Weekly newsletters

- Buy & download The Bulletin

- Comment on our articles

Noumenon: sci-fi furniture

We’ve all been there: You spend an afternoon at Ikea, come home with a flat-pack and then spend the rest of the night trying to follow the cryptic instructions using only a tiny Allen key to create a new piece of furniture. What if instead you could bring home a package the size of a box of cornflakes, plug it into a socket and wait 15 minutes while it transforms itself into an armchair?

“It’s a working space and living space, and also a sort of lab,” says Carl De Smet, as he puts the finishing touches to a pre-prototype of his expanding furniture in his Brussels studio home. De Smet recently made headlines around the world when he released a video on YouTube of his expanding furniture. He’s currently in talks to find an industrial-scale manufacturer and backers who will bring the product to market.

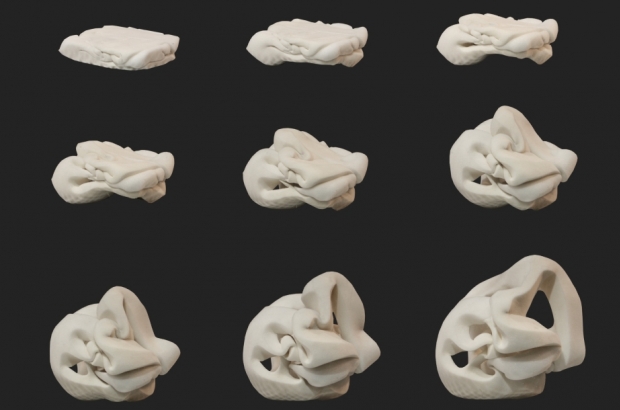

The video explains the process very clearly: A piece of furniture – the video shows a chair, so we’ll stick to that as an example – is constructed from shape-memory polymer (SMP) foam, either by milling a solid block or by injection moulding. The chair is then heated in a large press, which crushes it into a solid block or cylinder of dense foam.

This is the packaged shape, the form in which the product is sold. When it’s bought, the process is reversed: when 70-degree heat is applied, the chair returns to its original shape. Once it’s cooled again, it’s permanent.

Hot topic

How the process works is complex but comes down to the form of polymers. “If you look at polymers under a microscope, they have a kind of spaghetti structure, and inside the spaghetti are cross-links,” De Smet explains. The process involves creating cross-links chemically to fix the form and the triggering mechanism.

“So when you squeeze it down, it loses its shape. But it always wants to come back to its original shape. Every time you compress or stretch it, it remembers the connection points and cross-links.”

The choice of 70°C, he says, is to prevent accidents during transport. A lorry filled with packaged furniture might be stuck in traffic on a warm day, say, only to find the packages start to spring apart like popcorn. The choice of the high temperature, however, is problematic.

At the moment, the process of applying heat to transform the temporary shape – the slab, De Smet calls it – requires a home sauna. De Smet is experimenting, however, with the use of electricity as the trigger for the metamorphosis. That would mean that the consumer would just plug the product into a wall outlet. In theory, even larger pieces such as sofas or even guest beds could be transformed and reverse-transformed to suit the owner’s needs.

Public introduction

It all sounds like something a scientist might stumble upon by accident, but in fact SMPs have been around for about 20 years, De Smet says. “This is part of a research project we’ve been working on for seven years, and now we are finally almost ready for prototypes.”

A decade ago, De Smet was doing research with shape memory alloys, “which also have a memory effect, and we were looking for applications that could be mass-produced. But the wires are so expensive we turned our attention to polymers.”

There was just one problem: The polymers were not as strong as the metals, “so we had to move to a kind of lightweight material, and that’s how we came up with the foam. Foam is really a flexible material, but at room temperature this material becomes strong and rigid.”

Last month, De Smet and design consultancy Noumenon took the furniture to an exhibition in Milan, and the attention they received there – not least because of a short TV spot on the BBC – sparked major interest.

Substance over style

De Smet studied experimental art in Brussels, but he’s less interested in the art of design than the science. “The whole time I was studying, I was moving back and forward between art and materials science, so for me, when I think about design, it’s always in the context of material properties. I’m less interested in the aesthetics than the multifunctionality. These materials have quite a lot of functional approaches because they have a memory. If you can remember shapes you can do all kinds of things.”

For the time being, that involves bringing the designs to market. “Right now we are dealing with a manufacturer, so we have to make a deal. We had some really good feedback from Milan, so now we’re following up on those contacts to see who our partners might be in the future.”

And does he have any other bright ideas on the horizon? “Well, yes, we have a number of different ideas. But we’re not talking about that for the moment.”

This article was first published in Flanders Today